Filtration

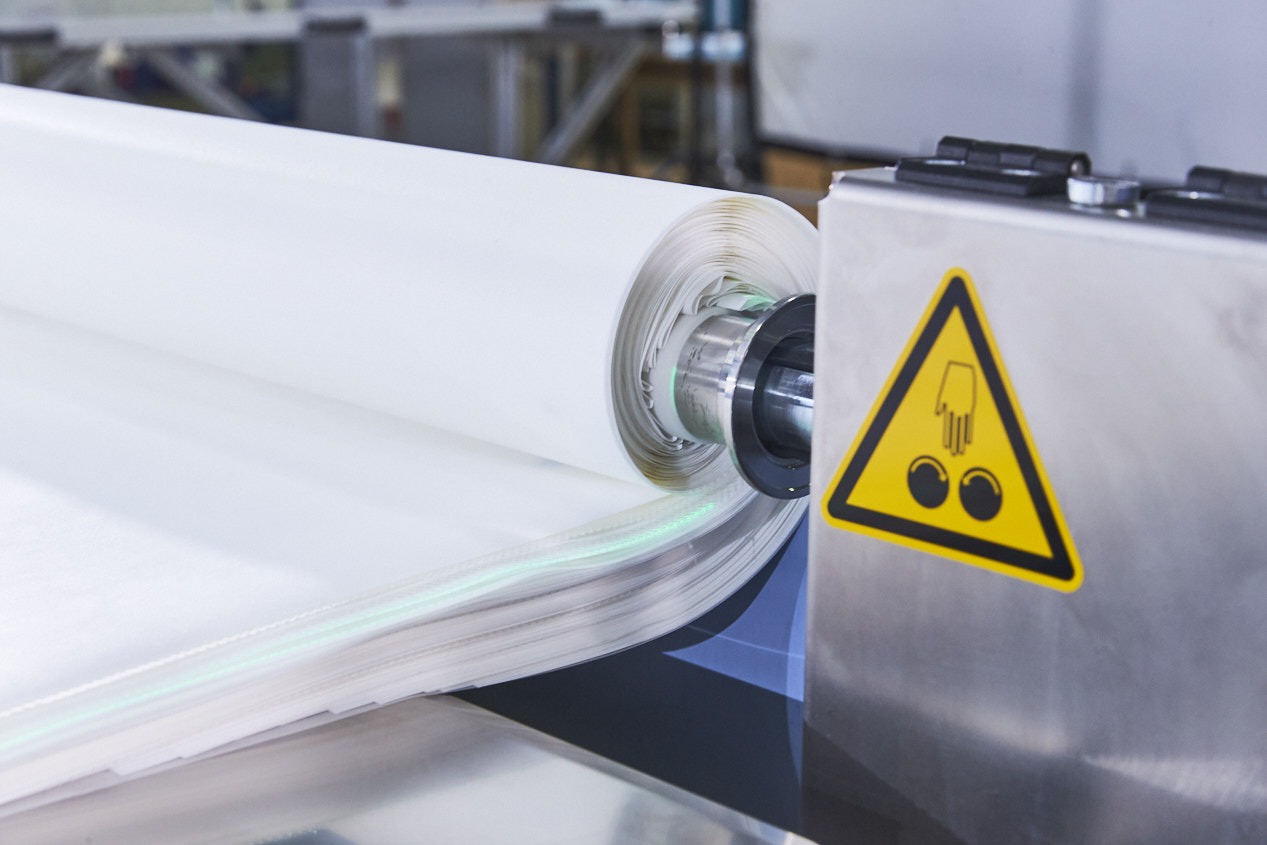

Custom-tailored machines for the manufacture and processing of filters.

Thanks to our modular design, we are able to manufacture the most complex products in the field of filtration automatically. To do this, we combine individual functions into an overall solution.

GFM's Custom Spiral Wound Element Machine

Tailored Machinery Solutions for a Spiral Wound Element

In the advanced world of membrane technology, there's a growing interest in specialized membranes tailored to specific applications. GFM Converting Solutions provides these through our Spiral wound element machine, producing spiral wound elements for diverse filtration types, from reverse osmosis to micro-, ultra-, and nanofiltration.

Understanding Membrane Filtration Process and its Types

Membrane filtration essentially lets certain substances pass through a barrier while blocking others. For water, this means clean water passes through the barrier, removing impurities or harmful microorganisms. Among various water treatment methods, membrane filtration stands out as a notably efficient and economic method.

Micro- and Ultrafiltration

In microfiltration (MF) and ultrafiltration (UF) processes, contaminated liquids are filtered by retaining particles larger than the membrane's pore size. The purity level of the resulting flow depends on initial impurities and the membrane's pore size.

Reverse Osmosis and Nanofiltration

Reverse osmosis (RO) and nanofiltration (NF) processes resemble MF and UF but involve pressure being applied to the liquid to pass it through the semi-permeable membrane. They can also filter out smaller molecules, like pesticides or agricultural chemicals.

Benefits of GFM's Spiral Wound Element Machine

Our Spiral wound element machine has a clear advantage over other filtration machines: exceptionally high packing density with reduced energy consumption. The design is based on multiple membrane pockets with spacers in between, wrapped around the central permeate tube. Thanks to its precise construction, the permeate emerges only on the side of the permeate tube, with the appropriate spacer chosen based on the medium's viscosity.

Our Custom Machinery Solutions for Spiral Wound Filtration Applications

With extensive experience in designing and manufacturing custom machinery solutions, we produce high-quality elements tailored to your needs and production processes. We handle a vast array of spiral wound filtration elements and serve a broad application spectrum, from desalination to food, beverage, dairy, biotechnology, and pharmaceutical industries.

To offer you an even deeper insight into the functionality and versatility of our machinery, we've produced a detailed YouTube video. In this video, we take you behind the scenes at GFM and showcase our state-of-the-art Spiral wound element machine in action. Click right to watch the video and learn more about the technology driving our Custom Machinery Solutions.

Applications of GFM's Spiral Wound Element Machine

From the food industry to biotechnology, our machine's application areas are vast. They're used in milk standardization, cheese-making, brine clarification, fruit juice production, egg processing, gelatin, blood, starch, and yeast treatment, and separating microorganisms and cells. Wine filtration is another key application.

The membrane and module's careful selection plays a crucial role in the filtration process's success, especially in sensitive areas like the food and beverage industry. GFM understands these nuances and offers tailored machinery solutions for every unique need.

For more information about our Spiral wound element machine or our other machinery solutions, feel free to contact GFM Custom Machinery Solutions.

„Discover More: Contact GFM Custom Machinery Solutions!"

In addition to our innovative Spiral wound element machine, GFM offers other spiral winding machines and various custom machinery solutions. Our ongoing drive for innovation and precision ensures these machines meet the highest industry standards. Whether you're looking for specialized winding solutions or other custom machinery solutions for different applications, we are your reliable machinery partner. Learn more about our range of machines and their applications.