Manufacturing systems for face masks

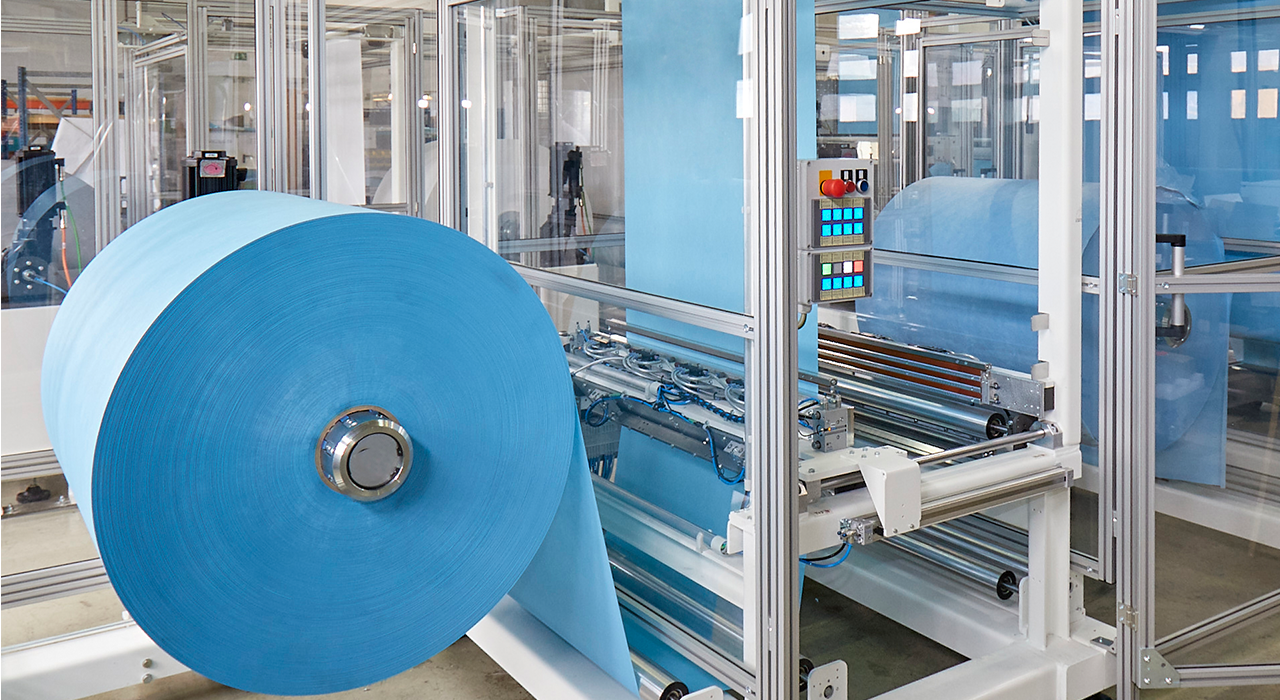

his machine produces surgical face masks. Mainly flat disposable masks, which consist of a mask molding unit and 2 ear loop welding units. The machine essentially consists of::

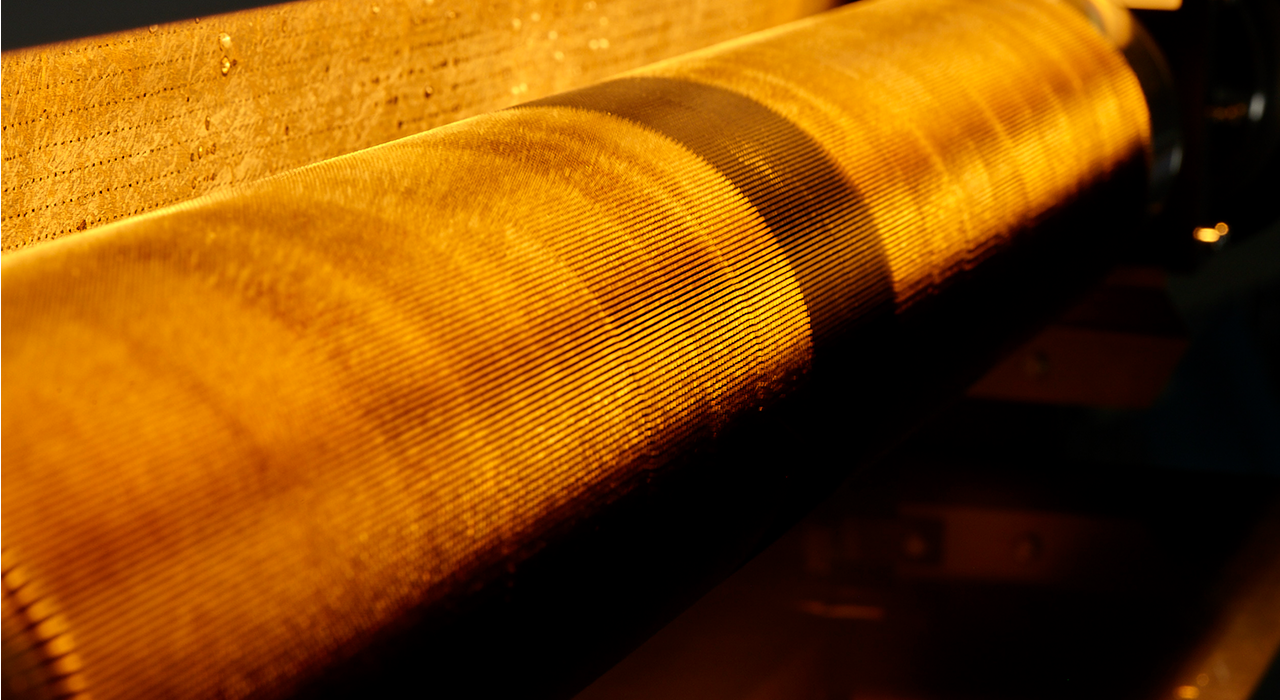

- Feed and processing of the base material roll (up to 4 rolls)

- Insert and cut the nose clip

- Sealing the individual layers

- Automatic cutting of the mask contour

- Feed the ear loops with automatic welding process

The masks with 2 to 4 layers (without edge sealing) can be adapted to your specifications. The manufacturing plant is characterized by high reliability and simple operation. Furthermore, the manufacturing plant meets the European quality and safety standards.